Report

Expertise in canning

KHS and Ferrum adopt pioneering role in hygienic

machine design

KHS and Ferrum: hygienic

machine design crucial

“Our mutual customers have exacting

standards when it comes to the quality

of their products,” states Marc

Zubler, head of Sales and Product

Management at Ferrum. An optimum

hygienic machine design that reflects

the current demands and requirements

of the market is just as important

as the consultancy service that

goes with it.

Härtel claims both companies share

a deep understanding in this area;

many years of partnership have created

systems that are perfectly attuned

to one another. “We offer a complete

package of first-class technology

and advice. Our jointly developed

filler/seamer block gives our customers

plenty of added value,” Zubler declares.

Flexible, hygienic and robust:

the Innofill Can C

KHS provides two fillers for the can

segment that have long proven themselves

on the market: the Innofill Can

DVD for the high-performance range

and the Innofill Can C designed for

small to medium filling quantities.

Thanks to a new addition to the series

that boosts capacity to up to 60,000

cans per hour, the Innofill Can DVD’s

little brother can now be integrated

into lines with higher outputs even

more effectively. It is also extremely

flexible, enabling several different

products and formats to be processed

on a single line. “The Innofill Can C is

distinguished by its fast format

changeovers and setup times. This in

turn increases the availability and

economy of the system,” is how Härtel

describes the benefits of this particular

filler.

An increasing number of beverages are being filled into

cans worldwide, with the diversity of products seeing a

similar increase. It is for precisely this reason that canners

make particularly high demands of flexibility and

the hygienic design of their machinery. KHS and Ferrum

take on a pioneering role in this field. Their technical

systems, perfectly attuned to one another thanks to

many years of partnership, enable beverage producers

to market high-quality products that are hygienically

flawless. The compact Innofill Can C from KHS, for example,

is convincing with its flexible, taste-neutral filling,

among other features. This is supplemented by matching

seamer systems FC06 and FC08 from Ferrum which with

their open design are especially easy to clean. Combined,

both machines make for a very efficient filling process.

The world demand for trend beverages

such as hard seltzer, energy

drinks and craft beer continues unabated.

Here, the can is often the container

of choice, says Manfred Härtel,

filling technology product manager

at KHS. “It’s light, easy to recycle and

keeps products fresh for longer with

its excellent barrier properties.” This

type of container is increasingly being

favored for established beverages

such as soda pop, water and mixed

beer beverages. According to Härtel,

this is prompting a good number of

beverage filling operations to increase

its range in the can segment

and fill more and more different products

on the same line. “This means

higher demands are made of the machine’s

flexibility and hygiene,” the

KHS filling expert explains. “For the

greater the product variety on a line,

the greater the risk of contamination

and flavor carryover.”

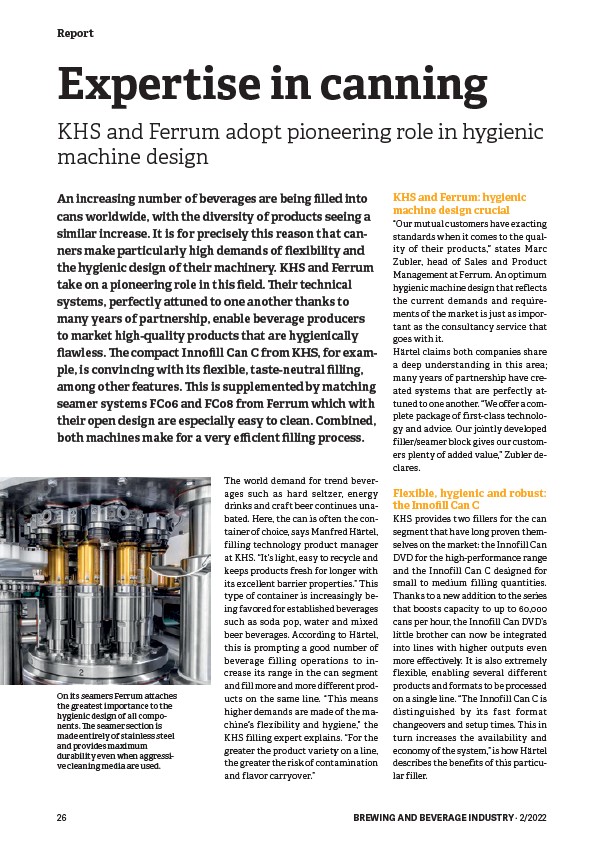

On its seamers Ferrum attaches

the greatest importance to the

hygienic design of all components.

The seamer section is

made entirely of stainless steel

and provides maximum

durability even when aggressive

cleaning media are used.

26 BREWING AND BEVERAGE INDUSTRY · 2/2022